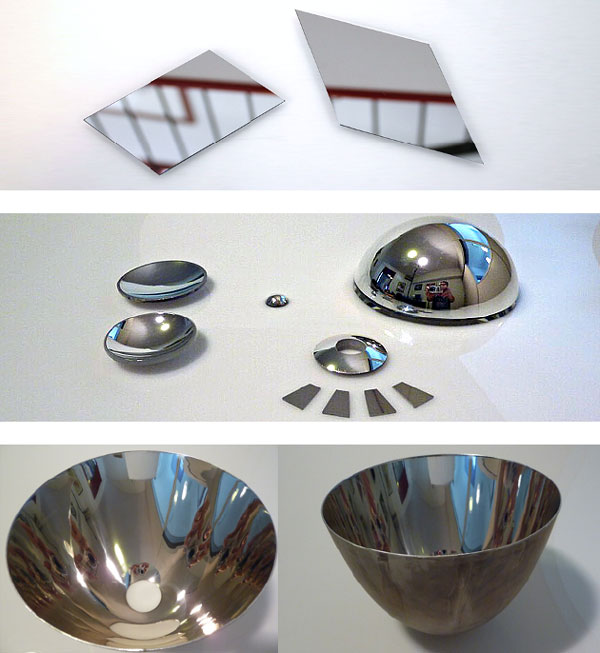

Optical components

The optical component division of Lobre is manufacturing all kinds of customized optical components since more than 74 years, for instance spherical lenses, cylindrical lenses, asphere lenses, mirrors, prisms, beam splitters, dome’s, optical windows, diffusors, filters, etc.

Tailor-made production to high quality standards

No other factor determines image quality more than the individual quality of each of the optical elements used in optical systems or objectives. The challenge is to utilize the light entering the optical system and focus it into an image with minimal loss and distortion to obtain images as bright and sharp as possible. There is a vast array of conditions that ultimately determines the overall performance of an optical system, such as the precision and quality of the lenses, mountings, coatings, and used optical glass types.

All those components are specifically manufactured upon the customer’s design and have one element in common: they are made up to the highest reachable quality standards. Every single optical component is always thoroughly checked by the most advanced metrology instrumentation and individual quality reports can be provided when required.

Spherical lenses

The most common used lens types are spherical lenses and they are used in many different applications to collect, focus and diverge a light beam by means of refraction.

Lobre manufactures any kind of customized spherical lenses in the UV, VIS, NIR and IR range:

- From Ø4 mm up to Ø440 mm with a surface quality (S&D) up to 10:5 and very precise Centering (30 arc seconds);

- the highest surface accuracies possible with Radii from 2 to infinity;

- Manufactured from any kind of optical glasses, including high index glasses, Quartz, Fused Silica, Sapphire, Germanium, ZnSe, and other UV/IR materials;

Such lenses are requested as single lenses, or as lens groups made of two or more components bonded together, such as achromatic doublets or triplets. By combining two or three lenses into one single optical element it is possible to manufacture so-called achromatic or even apochromatic optical systems.

Such lens groups allow to reduce drastically chromatic aberrations and are manufactured with specific high-precision equipment of Trioptics to ensure maximum precision in element alignment. Such elements are widely used in high quality vision systems, life science and in microscopy.

100% of our lenses are fully Quality Checked at each stage of the manufacturing process and our advanced ERP system allows total production tracking at each stage of the manufacturing process.

Aspheric lenses

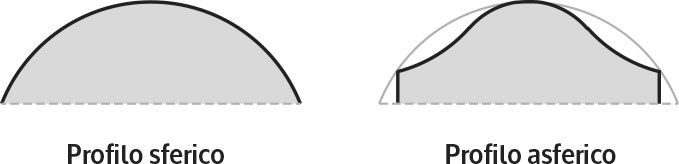

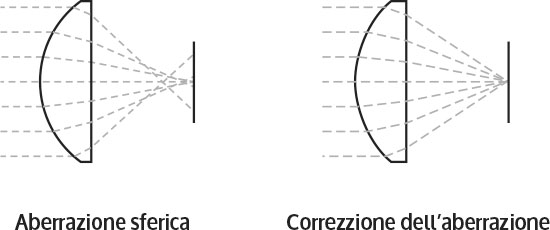

Aspheric lenses have a more complex surface geometry, since they do not follow a proportion of a sphere. An aspheric lens is rotationally symmetric, with one or more non-spherical surfaces that differ from the shape of a sphere.

The main advantage of such type of lenses derives from their ability to reduce significantly spherical aberration. Spherical aberration occurs when a lens is not capable to focus all the incident light on the exact same point. Due to the very nature of an aspheres irregular surface shape it allows to manipulate simultaneously the many wavelengths of light, allowing to focus all the light on the same focal point, resulting thus in sharper images.

All aspheric lenses, regardless of being convex or concave, can’t be defined by a single radius of curvature, and in this case their shape is defined by the Sag Equation, and it’s variable, “k” defining the overall shape of the aspheric surface.

While aspheres offer some advantages over standard lenses, their unique configuration makes them more difficult to manufacture and optical designers must therefore weigh the performance benefits against their higher cost. Modern optical systems that use aspherical elements in their design can lead to reducing number of lenses required, allowing to create lighter, more compact systems, while still maintaining, and often times exceeding, the performance of systems using only spherical elements. Even though more expensive than traditional lenses, aspheres could be an attractive alternative and powerful option for high performing optical systems.

Aspheres can be manufactured using several methodologies. Basic aspheres are manufactured using injection molding technology, allowing to realize various types of aspheres, mainly for light condensing purposes (lightning sector). More precise and complex aspheres require individual CNC generation and polishing, like realized with innovative HydroSpeed® Polishing Technology machinery (Optotech) used in Lobre.

Lobre is able to design and supply various types of asphere elements both in semi-optic and optical glasses and even in plastic materials, such as polycarbonate, polyurethane or silicone.

Mirrors and optical windows

Optical Mirrors are composed of a sheet of glass (called substrate) that has one top surface coated with a highly reflective material, such as aluminum, silver or gold, and it allows to reflect efficiently as much as possible light.

They are used in a vast variety of industries, such as life sciences, astronomy, metrology, semiconductor, or solar applications, including beam steering, interferometry, imaging, or illumination.

Lobre offers a wide range of customized flat and spherical optical mirrors, all created with state-of-the-art evaporation coating techniques and available with several reflective coating options, including Protected Aluminum, Enhanced Aluminum, Protected Silver, Protected Gold, and customized Dielectric coatings.

Optical windows are flat, optically transparent plates that are most commonly used to protect optical systems and electronic sensors from the outside environment.

They are designed upon customer needs to maximize transmission in a specific desired range of wavelength and at the same time should minimize undesired phenomena such as absorption and reflection.

Since optical windows don’t introduce any optical power into a system, such windows should be selected mainly based upon their physical properties, such as transmission rate, optical surface specifications, and it’s mechanical properties (thermal performance, durability, scratch resistance, hardness, etc.) in order to make them match exactly your specific application.

Lobre offer the possibility to realize any type of customized optical window, in a wide range of materials such as optical glasses like N-BK7, UV fused silica, Germanium, Zinc selenide, Sapphire, Borofloat and extra clear glass.

Custom optical precision mirrors

High precision optical mirrors are increasingly used in optical systems where dimensional constraints require more compact systems. The purpose of these particularly efficient mirrors is to deflect the light beam without loss of energy, while maintaining the image quality unchanged.

This type of mirrors, also called first surface optical mirrors, and can reach reflectivity levels of even over 99%, depending on the type of metal coating chosen (aluminum, pure silver, pure gold, dielectric) and the optional protective layer applied.

The substrate used for their realization (optical glass, vetroceramics) requires a particularly high quality and must be rectified and polished with very high precision.

Lobre has been manufacturing a wide range of high reflectivity or partial reflectivity precision optical mirrors, customized for industrial, electromedical, aerospace and scientific applications for over seventy years with surface qualities up to λ/20. All the mirrors are produced by the evaporation process in a vacuum chamber PVD with ion and plasma source.

The following types of reflective and semi-reflective mirrors are manufactured tailored to your requirements:

- Flat mirrors

- Concave and convex spherical mirrors

- Electroformed mirrors

- Free-form mirrors with complex geometries

High-tech Optical Filters and polarizers /waveplates

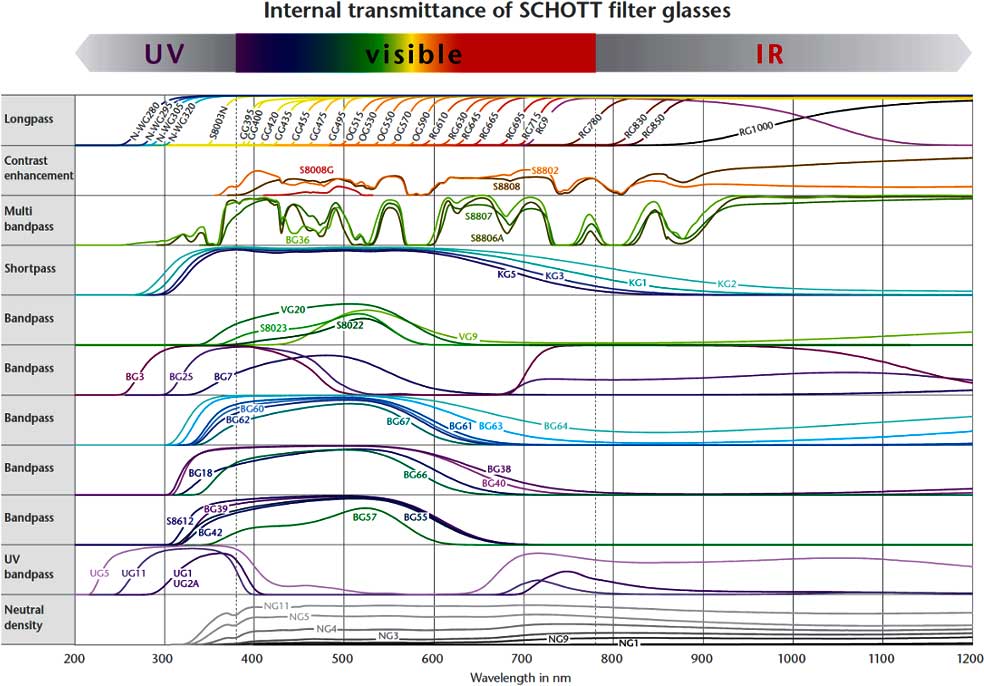

An optical filter is a special type of flat window that selectively transmits or rejects a specific range of wavelengths (=colors) when placed in the optical path.

The optical properties of filters are described by their frequency response, which specifies how the incoming light signal is modified by the filter, and can be displayed graphically by its specific transmission diagram.

Lobre offers a vast range of different types of customizable optical filters:

- Absorptive filters are the simplest ones, where the basic composition of the filter substrate or applied specific coating layers absorb or fully block undesired wavelengths.

- More complex filters belong to the dichroic filter category, or also called “reflective” or “thin film” filters. Dichroic filters use the principle of interference: their layers form a sequential series of reflective and/or absorptive layers that allow to create very precise behaviour within the required wavelengths. Dichroic filters are particularly suited for precise scientific work, since their exact wavelengths (colour range) can be controlled very precisely by the thickness and sequence of the coatings. On the other hand, they are usually more expensive and delicate than absorption filters.

Lobre manufactures and supplies the following types of optical filters that can be made according to the customer’s design:

- Neutral Density filters (ND): this type of basic filters is used to attenuate incident radiation without altering its spectral distribution (like the full range of Schott filter glass).

- Color Filters (CF): Color filters are absorption filters made of colored glass which absorb light in specific wavelength ranges in varying degrees and let other ranges pass to a major extent. In this category belong also the Schott KG line of heat absorbing glass filters, that allow to reduce the amount of heat transmitted through an optical system and thus absorbs efficiently infrared radiation and dissipates the accumulated energy into the surrounding air.

- Edgepass/Bandpass filters (BP): Optical Bandpass Filters are used to selectively transmit a portion of the spectrum while rejecting all other wavelengths. Within this range of filters Longpass filters allow only higher wavelengths to pass the filter as Shortpass filterslet pass only smaller wavelengths. longpass and shortpass filters are very useful for isolating regions of a spectrum.

- Dichroic filters (DF): A dichroic filter is a very accurate colour filter used to selectively pass light of a small range of colours while efficiently reflecting other colours.

Lobre design and realizes customized high-performance filters in longpass, shortpass, bandpass, bandblocking, Dual bandpass and color correction over a wide range of wavelengths for applications that require optical stability and excellent durability. Please contact Lobre for further information or requests for quotation.

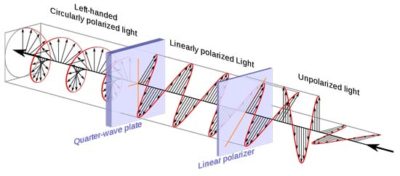

Polarizers/waveplates

A polarizer or also called waveplate or retarder is an optical device that alters the polarization state of a light wave travelling through it.

Two common types of waveplates are the half-wave plate, which shifts the polarization direction of linearly polarized light, and the quarter-wave plate, which converts linearly polarized light into circularly polarized light and vice versa. A quarter-wave plate can be used to produce elliptical polarization as well.

Polarizers or also called waveplates are constructed out of a birefringent material (such as quartz), for which the index of refraction is different for light linearly polarized along one or the other of two certain perpendicular crystal axes.

Polarization components are used in imaging applications to reduce glare or hot spots, enhance contrast, or to perform stress evaluations. Polarization can also be used to measure changes in magnetic fields, temperature, molecular structures, chemical interactions, or acoustic vibrations. Polarizers are used to transmit a specific polarization state while blocking all others. Polarized light can have linear, circular, or elliptical polarization.

The behaviour of a waveplate (that is, whether it is a half-wave plate, a quarter-wave plate, etc.) depends on the thickness of the crystal, the wavelength of light, and the variation of the index of refraction. By appropriate choice of the relationship between these parameters, it is possible to introduce a controlled phase shift between the two polarization components of a light wave, thereby altering its polarization.

Lobre’s high performance Thin Film Polarizers are made with state-of-the-art thin film vapour depositing coating technology for optimal performance. The polarizers are available with polarizing coatings on both sides of the polarizers, or a polarizing coating on the input face and a high quality multilayer anti-reflection coating on the output face. Please contact Lobre for further information or requests for quotation.

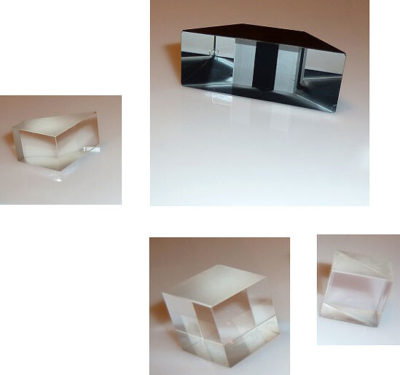

Prisms /Beamsplitters

A prism is a transparent optical element with flat, polished surfaces that refract light. At least two of the flat surfaces must have an angle between them. The most important parameters of a prism are the angle and the used material.

Prisms are widely used in splitting, depolarization, polarization, image orientation, dual channel instruments, etc. There are numerous different types of prisms, such as polygonal prisms (Light is typically deflected at 45, 60, 90 and 180 degrees), Pentagonal prisms(that have a stable light deviation, always 90 degrees regardless of the optical axis and light and are used for measurement, laser scanning and alignment), Dove prisms (a reflective prism used to invert an image. It is made up of a truncated right angle prism).

Prisms are sometimes used for the internal reflection at the surfaces rather than for dispersion. If light inside the prism hits one of the surfaces at a sufficiently steep angle, total internal reflection occurs and all of the light is reflected. This makes some types of prisms extremely efficient mirrors in some situations.

A beamsplitter is an optical device that allows to split an incident light beam in two or sometimes more separate beams, which may not have the same optical power.

There are a large variety of different types of beamsplitters, but they can be divided into the plate beamsplitter and the cube beamspliter categories.

They are widely used numerous optical based systems, such as interferometry, autocorrelators, spectroscopy, projector systems and laser systems. Please contact Lobre for further information or requests for quotation.